- Full In-die process monitoring of every fastener

- Fastener Lock-Out System with box label scanning

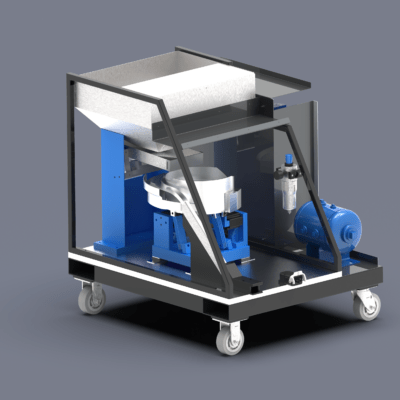

- Distribution HUB available for multiple head applications which reduces setup and changeover times to a few minutes

- End-to-End Traceability of all fasteners